Metal Seal Precision was formed in November 2011 with the merger of Arrow Manufacturing and Metal Seal & Products. The new company is headquartered in Mentor, OH. Today we are large enough to serve but small enough to care. As a family owned business that cares about its employees and community we hope to have the opportunity to grow our business with customers that want to join us in making the world a better place.

Today’s Metal Seal Precision is the result of a blending of the rich history of two former competitors that have been serving the machined parts industry for more than 50 years.

The History of Arrow Manufacturing

Arrow Machine was founded on January 1, 1967 in Cleveland, Ohio. Its three employees included its founder, John L. Habe, II, and was located in Cleveland, Ohio in a 3,000 square foot garage space.  The original equipment included two four-spindle Acmes, one six-spindle Conamatic and one six-spindle New Britain. All the equipment was vintage, but serviceable. In 1972, Arrow relocated to a 10,000 square foot facility with partially automated chip handling. In 1981, we began construction of a new 18, 000 square foot facility in Mentor, Ohio with clean air purifiers, improved shop lighting, and dramatically expanded material handling capabilities. In 1992 we added CNC machining capabilities and by 1998 we had grown to a 40 screw machine shop with 17 CNC machines and began construction of yet another manufacturing plant in Mentor, OH. In 1999 the company moved into a new 80,000 square foot, worker-friendly and highly efficient screw machine facility. Our ability to anticipate the direction of machine tool and cutting tools industries enabled us to continue to grow. From 2002-2003 we added 10 German and Italian built screw machines. In 2004, we added our first rotary transfer machines. Like everyone else in the machining industry, the 2008-2009 recession forced Arrow to do what was necessary to survive two of the worst years in U.S. automotive industry history. But survive we did and we emerged from the downturn a much leaner and efficient company that was ready to resume its quest for growth. The original equipment included two four-spindle Acmes, one six-spindle Conamatic and one six-spindle New Britain. All the equipment was vintage, but serviceable. In 1972, Arrow relocated to a 10,000 square foot facility with partially automated chip handling. In 1981, we began construction of a new 18, 000 square foot facility in Mentor, Ohio with clean air purifiers, improved shop lighting, and dramatically expanded material handling capabilities. In 1992 we added CNC machining capabilities and by 1998 we had grown to a 40 screw machine shop with 17 CNC machines and began construction of yet another manufacturing plant in Mentor, OH. In 1999 the company moved into a new 80,000 square foot, worker-friendly and highly efficient screw machine facility. Our ability to anticipate the direction of machine tool and cutting tools industries enabled us to continue to grow. From 2002-2003 we added 10 German and Italian built screw machines. In 2004, we added our first rotary transfer machines. Like everyone else in the machining industry, the 2008-2009 recession forced Arrow to do what was necessary to survive two of the worst years in U.S. automotive industry history. But survive we did and we emerged from the downturn a much leaner and efficient company that was ready to resume its quest for growth.

History of Metal Seal

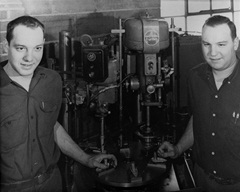

Metal Seal & Products, Inc., was established by two brothers, Edmund B. and Irving C. Diemer. It began operations in a small shop on the east side of Cleveland, Ohio in 1949 with a handful of WWI surplus indexing turret lathes. Eventually, Metal Seal purchased a company in Pennsylvania that made water faucets for kitchens and bathrooms. All the equipment and work in the Pennsylvania shop was brought back to the plant in Cleveland.

Irving Diemer (left) and Ed Diemer founded

Metal Seal in 1949. In the late 50’s, the company moved into a larger building in Euclid and expanded operations. The majority of customers served were in the plumbing industry along with some new automotive customers. In 1956 Metal Seal became an active member of the National Screw Machine Products Association (NSMPA), a National Trade Association based in Brecksville, Ohio. Ed Diemer served as President of the Association in 1993.

In 1996, at the NSMPA annual meeting, Ed and Irv each received a Gold Micrometer Award marking 40 years of service to the Association. NSMPA later became the Precision Machined Products Association (PMPA), an organization in which Metal Seal Precision, Ltd. is still a member today.

In 1965, Metal Seal moved to a brand new 30,000 sq. ft. facility in Willoughby, Ohio. The new plant was soon filled with Acme, Davenport, and Brown & Sharp screw machines, supported by inspection and secondary equipment. The new plant was fully air conditioned and took advantage of special utility rates as an “All Electric Building”… a fact that was publicized in TIME Magazine by the Cleveland Electric Illuminating Company. This new location fueled even more growth and Metal Seal began construction of a 10,000 square foot building on a lot adjacent to the main plant. While Building #2 housed secondary equipment and a bright dip operation for brass plumbing parts, the company was also quickly becoming a major supplier to the automotive industry.

Over the years, Metal Seal continued to expand and soon became recognized as a world class supplier of automotive brake system components while still serving customers in the plumbing, electronics and medical industries. Through a combination of buying and building additional capacity throughout the 80’s & 90’s, Metal Seal added another 100,000 square feet of manufacturing space and added in-house automated anodizing and zinc plating capabilities. A recycling system controlled by the very latest technology was installed to treat and reuse the plating line rinse water.

Irving C. Diemer, Sr.

In June of 2009, Ed and Irv both officially retired from their management responsibilities. The new management team, led by President Alan Pirnat faced a host of industry-wide challenges and volatile economic times. In 2011, Arrow Manufacturing contacted Metal Seal about a possible merger of the two long-time competitors. Months of negotiation and team-work resulted in the formation of the new Metal Seal Precision, Ltd.

The New Metal Seal Precision

The merger of these two fine companies dramatically expanded our core competencies and the amount and variety of equipment we could bring to bear on a customer’s projects. As a result, the new Metal Seal Precision is better able to help customers drive cost out of the manufacturing process and get to market faster than ever before. |